Ever wondered what abbreviations like DN, PN, ½, WOG, and CWP letters on a valve mean? Curious about the markings on a valve body and what other letters might appear? Let’s dive in and explore.

The markings on a valve typically represent crucial information such as its size, pressure and temperature ratings, material composition, brand, flow direction, and certifications. These details are vital in proper selection, installation, and operation, ensuring the valve is used safely and correctly.

Fakahokohoko ʻo e Tohi

Tuʻu maʻu1. Valve Size Marking:“DN” pea mo “½” Fraction or Letters on Valve

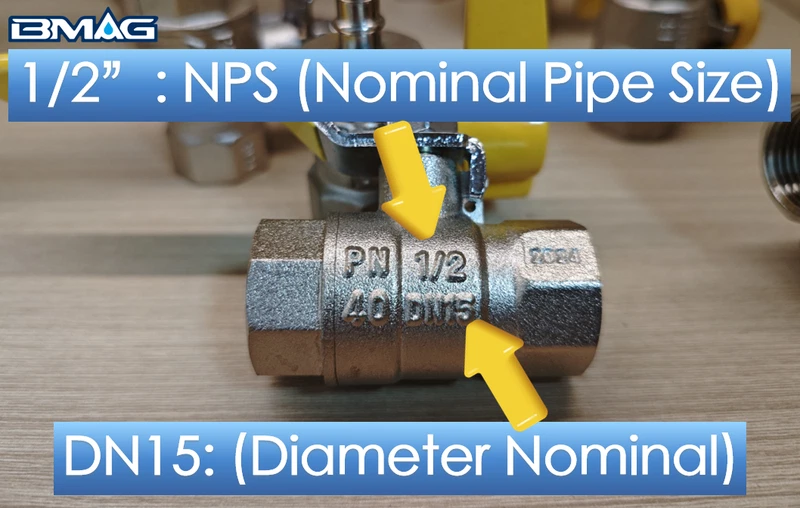

The valve size is its most fundamental parameter, indicating the nominal bore of the pipe it fits. It is typically marked in one of two ways:

- DN (Diameter Nominal): The nominal diameter, a metric unit (in millimeters) used in international (ISO) and European/Chinese (EN/GB) standards. Hangē ko ʻení, DN50 means the valve is for a pipe with a 50 mm nominal diameter.

- NPS (Nominal Pipe Size): An imperial unit (in inches) used in American standards (ASME/ANSI). Hangē ko ʻení, 4″ or NPS 4 indicates the valve is for a 4-inch pipe. Sometimes, only the number, such as 4, is cast on the body.

2. Valve Pressure Rating Marking: “PN” and Numbers on Valve

The pressure rating indicates the maximum working pressure a valve can safely withstand at a given temperature and is critical for selection.

- ISO/EN/GB Standards: Uses “Nominal Pressure” (PN), where the unit is bar. The PN value represents the pressure rating at room temperature. Ngaahi sipinga: PN16, PN40.

- ASME/ANSI Standards: Uses a “Kalasi” system, written as CLASS, CL, LB, or #. Examples include CLASS 150, 300#, or 150 LB. This represents a pressure-temperature curve, not a constant pressure value.

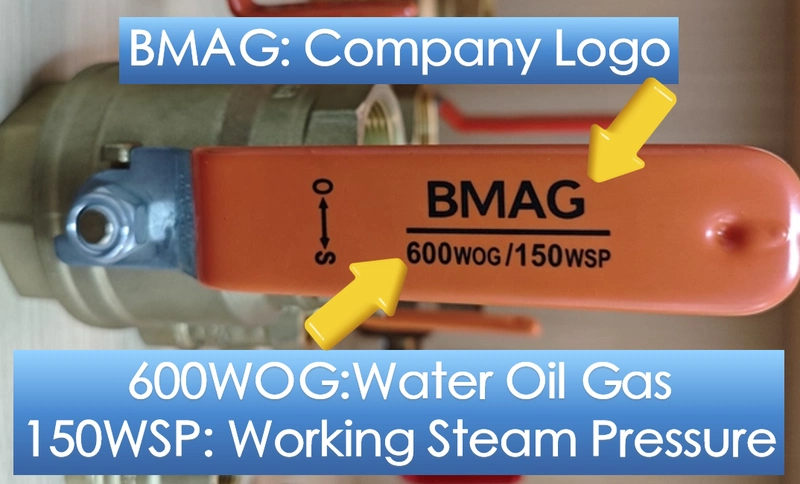

- General Purpose Ratings:

- WOG (Water, Oil, Gas): Indicates the pressure rating in psi for water, oil, and gas service at ambient temperatures. Example: 600 WOG.

- CWP (Cold Working Pressure): The modern equivalent of WOG, also indicating the maximum allowable pressure at ambient temperature. Example: 1000 CWP.

3. Valve Material Marking:

The material code is one of the most important markings, specifying the material of the main pressure-containing parts like the body and bonnet.

- Cast Carbon Steel: WCB is the most common grade.

- Cast Stainless Steel: CF8(equivalent to 304 SS), CF8M(316 SS), CF3(304L), CF3M(316L).

- Cast Alloy Steel: WC6, WC9(chrome-moly steel for high-temperature service).

- Forged Materials: A105(carbon steel), A182 F316(ukamea stainless).

- Lead Free: “LF” means lead-free material, including brass and bronze.

4. Valve Media Marking:

The specific service medium (e.g., “Sulfuric Acid”) is generally not marked. Suitability for a medium is determined by the valve’sNāunau. Neongo ia, for certain special services, specific markings are used:

- WOG: suitable for normal Water Oil Gas medium

- S: Steam medium

- G: Gas medium

5. Valve Brand Marking:

This refers to the manufacturer’s trademark, logo, or name abbreviation, used to identify the producer. Hangē ko ʻení, “BMAG” or a unique symbol.

6. Valve Flow Direction Marking:

For unidirectional valves like globe valves, vakaiʻi e valves, and angle valves, a clear arrow symbol(→) must be cast or stamped on the body. This arrow indicates the correct direction of media flow. Incorrect installation can lead to malfunction or damage.

7. Valve Certifications Marking:

These markings indicate that the valve complies with specific regional or industry regulations and standards.

- CE: Abbreviation for “Conformité Européenne,” indicating compliance with EU safety, health, and environmental protection standards, required for market access in Europe.

- API: The American Petroleum Institute monogram is commonly found on valves used in the oil and gas industry.

- FSA: Canadian Standards Association, a certification required to sell equipment in Canada.

- UL: Underwriters Laboratories, certification is a safety certification provided by Underwriters Laboratories, a global safety science company. It signifies that a product, component, or system has been tested and meets specific safety standards.

Find Top-Quality Valves at BMAG.