Tabla contenidos

AlternarNuga̲. Nthuts'i ñut'i: Lead-Free Valves—The Inevitable Trend for Health and Regulation

1. Temu̲ ar 'na barbula mpe̲fi plomo?

'Nar barbula mpe̲fi plomo bí refiere ja 'nar barbula ho ya componentes jar contacto ko ar fluido (komongu ar komongu,, bola,, wa tallo) gi 'bu̲hu̲ hechos ar aleaciones cobre ko 'nar extremadamente hñets'i'i plomo (Pb) contenido— normalmente ≤0,25% jar ndamäni, pe nu'bya ≤0.1%.

'mu̲i principal ar xi hño ar dehe potable hingi xí contaminada ya plomo Komo fluye a través de ar barbula, ne pa ñäñho contenido plomo jar dehe, proteger ar nzaki pública.

2. Yogo'ä ar necesitan válvulas hinda plomo?

- requisito nzaki: plomo ge 'nar metal hñei tóxico. Chronic ingestion can cause severe damage to the nervous system and internal organs, particularly in children.

- Regulatory Compliance: Major global markets have mandated strict standards for materials that come into contact with potable water.

3. Global Policies Driving Lead-Free Adoption

- The United States: The most significant regulation is the SDWA-1417 (Safe Drinking Water Act), which took effect in January 2014. This law mandates that the wetted surface of any device used for conveying or dispensing potable water must contain no more than 0.25% lead. Certification NSF YÁ ANSI 372 is required.

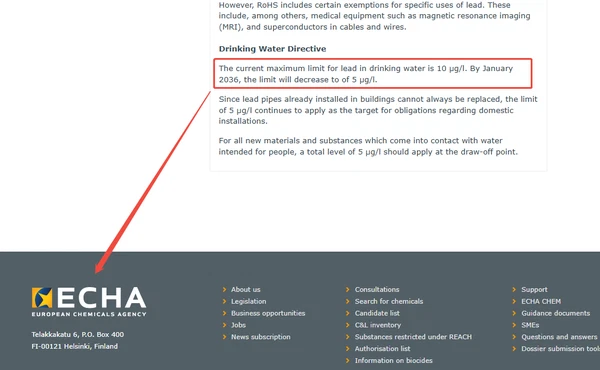

- Europe: The European Union’s revised DWD(Drinking Water Directive), implemented in Enero 2021, sets the maximum acceptable concentration for lead in drinking water: 10 µg/L. DWD sets a new limit of 5μg/L, which must be achieved by all EU member states by 2036. Member states enforce this through national certification schemes, often requiring materials to contain less than 0.1% lead.

II. Ar “plomo” Misterio ja ya aleaciones cobre: función, hogu̲t'i, ne sustitución

1. The Role of Lead in Traditional Brass Alloys

In traditional brass alloys, lead exists as an insoluble phase at the grain boundaries. Its primary function is to enhance the machinability (making the alloy easier to turn, drill, and shape) while also increasing lubricity y wear resistance.

2. Can lead in copper alloys be substituted?

- The Challenge: When lead is removed, how can the alloy maintain sufficient machinability, mechanical strength, and corrosion resistance?

- Lead Substitution Elements: The main alternatives include:

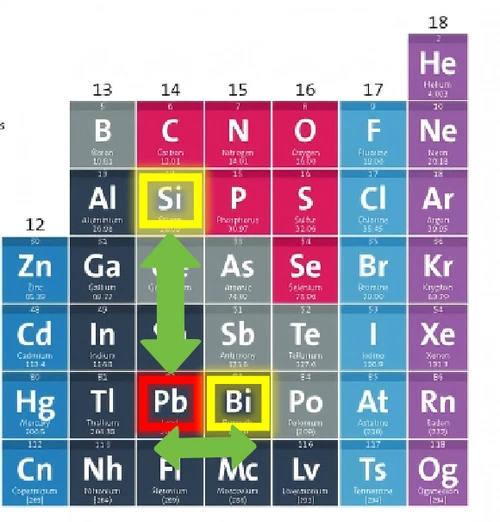

- Bismuth (Bi): ngetho ge 'nar fase hñets'i'i punto fusión da mejora significativamente ar rotura viruta ne ar 'bu̲'bya ar sustituto mäs hne ngatho.

- silicio (Hää): mejora resistencia ne resistencia ar corrosión (particularmente resistencia bí deszincificación) ne 'nehe tsa̲ da mejorar maquinabilidad.

Komo ar gi 'ñudi ja ar diagrama ar abajo, tanto silicio ne bismuto gi 'bu̲hu̲ cerca de plomo jar tabla periódica ne pe̲ts'i yá estructuras atómicas similares, resultando jar propiedades hñei comparables.

III. Temu̲ cobre hinda plomo ge mäs xi hño pa ya válvulas?

1. Requisitos ar rendimiento clave pa aleaciones barbula mpe̲fi plomo

- Plomo ultra hñets'i'i: Tsa da tsoni ko ntsoni reglamentarios ≤0.1%.

- Resistencia ar corrosión: Esencial pa ar durabilidad.

- Ndu nzafi & Clasificación ar presión: Pa xi hño funcionamiento confiable ya'bu̲ ar plazo.

2. Recomendado mpe̲fi plomo ne comparaciones

BMAG Destacados latón bismuto y latón silicio komongu ar opciones mäs xi ngu pa producir mar hñets'i rendimiento, válvulas cobre hinda plomo.

- C89833 (latón bismuto): excelente castability, making it a premier choice for cast valve bodies.

- C87800 (latón silicio): Outstanding strength and exceptional resistance to dezincification corrosion.

- C69300 (latón silicio / EcoBrass): A high-strength, high-performance option favored for forged valve bodies and balls.

- CW511L (Low-Lead Brass / Low Lead-Free): Often used where lead restrictions are less strict, or for cost-sensitive applications.

| Listed Grade | Region | Primary Characteristics / Application |

|---|---|---|

| C89833 | ASTM | Cast Lead-Free Bismuth Brass, suitable for potable water |

| C87700 | ASTM | Cast Silicon Brass |

| C87800 | ASTM | Cast Silicon Brass |

| C69300 | ASTM | High-Performance Silicon Brass, Forging |

| C87850 | ASTM | Cast Bismuth-Silicon Brass |

| CW509L | EN | Low-Lead Wrought Brass |

| CW510L | EN | Low-Lead Machinable Brass |

| CW511L | EN | Low-Lead Machinable Brass |

2. US UNS and European EN Naming Rules

- US UNS (Unified Numbering System): Uses the format “C” + 5 digits. C8xxxx series denotes Cast copper alloys, while C1xxxx through C7xxxx denote Wrought (deformed/forged) copper alloys.

- European EN (Euro Norm): Uses the format “CW” + 3 digits + letter. “C” for Copper, “W” for Form (W-Wrought, B-Cast), and the suffix “L” (for Low Lead) often indicates compliance with modern standards.

V. Temu̲ da 'ñets'i 'nar proveedor barbula mpe̲fi plomo mextha hño

1. Ar “Golden Rules” for Supplier Selection

- Rule 1: Verify the Material Test Certificate (MTC): Demand a complete Mill Test Certificate or chemical composition report for the raw materials. Ensure the lead (Pb) content strictly adheres to the required market regulations.

- Rule 2: Check Third-Party Certifications: Confirm that the final valve product holds necessary potable water contact certifications (such as NSF/ANSI 372, UPC, ACS, or WRAS).

- Rule 3: Assess Manufacturing Process: Premium lead-free alloys require advanced casting and/or forging technologies. Choose a supplier with proven expertise in these specialized manufacturing techniques.

- Rule 4: Check Migration Testing: The valve product has passed the final compositional migration testing.

2. BMAG’s Quality Guarantee

BMAG is committed to using high-quality, certified lead-free copper grades. We provide all necessary raw material documentation and product certifications, giving you complete confidence in your supply chain.

VI. zi ya nt'ot'e nu'bya: Ga japi ar jar contacto ko BMAG pa ár experto njäts'i ya barbula mpe̲fi plomo

BMAG delivers reliable, code-compliant válvulas cobre hinda plomo that meet the highest global health standards. Whether you are navigating regulations in North America, Europe, or other demanding markets, BMAG offers the most reliable and cost-effective solutions.

Contact the BMAG expert team today for your project’s specialized material reports and lead-free valve solutions!

Related article: Directiva ar dehe potable ar UE (DWD): Abastecimiento compatible válvulas latón hinda plomo