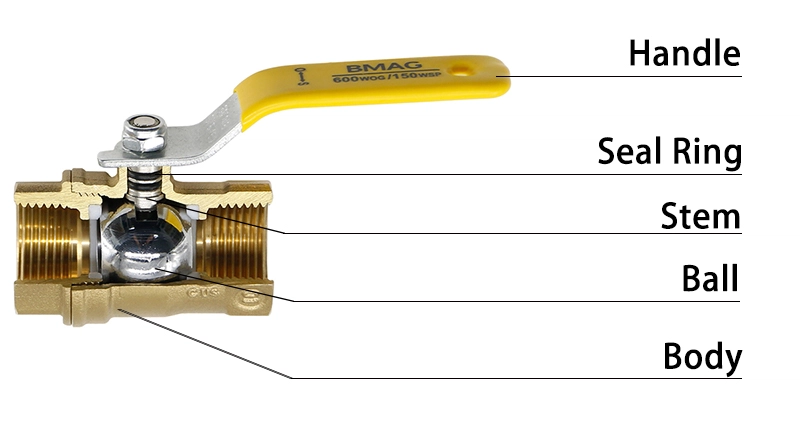

In the world of fluid control, the ball valve holds an irreplaceable position due to its superior performance. The source of all its advantages is concentrated in one seemingly simple yet precise component: the ball (or sphere). It is not just a switch, but the “heart” that determines the sealing performance, lifespan, and reliability of the valve.

As a factory deeply engaged in the manufacturing of valves, BMAG believes that thoroughly understanding every part of a valve is essential, as it enables buyers and users to better comprehend and use it. This article will provide a comprehensive analysis of the ball valve sphere’s function, materials, and manufacturing process. We will also explore common failures caused by the sphere and their solutions, citing relevant international standards to provide a comprehensive knowledge base behind a high-quality sphere.

Fizahan-takelaka

Toggle1. Core Function and Working Principle: The Art of 90-Degree Rotation

The core function of the sphere is to control the passage and shut-off of fluid. Its principle is both simple and highly effective:

Open: The bore (the channel through the sphere) is parallel to the pipe’s flow direction, creating a low-resistance, straight-through path for the medium to pass smoothly.

Close: By rotating the stem 90 degrees, the solid surface of the sphere becomes perpendicular to the flow direction. In tight contact with the seats on both sides, it forms a reliable shut-off seal.

This rapid 90-degree open/close action is the hallmark advantage of a ball valve compared to others like gate or globe valves.

2. Material Selection: The First Step to Success

The material of the sphere directly determines its ability to operate stably over the long term under specific temperatures, pressures, and chemical media. Choosing the wrong material is one of the leading causes of premature valve failure.

| Material Type | Common Grades | Key Features & Advantages | Typical Applications |

| Stainless Steel | SS304, SS316, SS316L, Duplex SS 2205 | Most widely used. Tena tsara harafesina fanoherana, especially 316/316L against chlorides. High sanitary grade, good strength. | Water treatment, chemical processing, food & beverage, pharmaceuticals, natural gas |

| Carbon Steel | A105 (Forged), WCB (Cast) | Cost-effective, high strength and hardness, suitable for high pressure & temperature. Poor corrosion resistance, usually requires surface coating. | Oil & mandatsa-dranomaso, steam systems, high-pressure pipelines |

| varahina | Hpb59-1, C36000 | Good thermal conductivity, excellent machinability, lower cost. Suitable for non-corrosive media. | Residential water lines, HVAC, gas pipes |

| Special Alloys | Monel, Hastelloy, Inconel, Titanium | For extreme conditions. Superior resistance to specific chemicals, high temperatures, and wear. | Seawater desalination, strong acids/alkalis, aerospace, offshore platforms |

| Ceramics | Zirconia (ZrO₂), Alumina (Al₂O₃) | Extremely high hardness, exceptional wear & corrosion resistance, excellent high-temperature stability. | Highly abrasive slurries, corrosive media with particulates |

3. Manufacturing Process: The Transformation from Blank to Precision Core

The creation of a high-quality sphere relies on a rigorous and precise manufacturing process.

- Material Selection & Forging/Casting: High-quality bar stock or pipes are selected. The initial blank is formed through hot forging or precision casting. Forgings offer superior mechanical properties.

- Rough Machining & Heat Treatment: CNC lathes perform initial shaping. This is followed by heat treatment (oh., solution annealing, quenching) to relieve stress, optimize the microstructure, and enhance material properties.

- Fine Grinding: This is the decisive step. A specialized sphere grinding machine is used to precisely control the sphericity (roundness) SY surface roughness (Ra). A mirror-like, perfectly round surface is essential for achieving low torque and zero-leakage sealing.

- Surface Treatment & Enhancement: For demanding applications, the sphere surface is enhanced with treatments like Electroless Nickel Plating (ENP), Hard Chrome Plating (HCr), na Tungsten Carbide Coating (TCC) to improve corrosion or wear resistance.

- Final Inspection: Using precision instruments like a Coordinate Measuring Machine (CMM), every sphere undergoes 100% inspection for dimensions, roundness, and surface finish to ensure it meets design standards.

4. Common Failures Caused by the Sphere: Causes and Solutions

Many valve failures can be traced back to the sphere. Understanding these issues helps in proper selection and maintenance.

| Common Failure | Root Cause (Related to the Sphere) | Solution |

| 1. Internal Leakage | – Scratches or Pitting on Sphere Surface: Solid particles in the media or improper operation cause scratches, breaking the seal line with the seat. – Sphere Corrosion: Incorrect material selection leads to chemical corrosion, making the surface uneven. – Loss of Roundness: Permanent deformation under high temperature/pressure or poor initial manufacturing precision prevents a perfect fit with the seat. | – Increase Surface Hardness: Select a harder base material or apply a surface hardening treatment (oh., TCC). – Proper Material Selection: Strictly choose corrosion-resistant materials (oh., Stainless Steel, Hastelloy) based on the media’s chemical composition, temperature, and concentration. – Ensure Manufacturing Precision: Partner with a reliable manufacturer that guarantees the required sphericity and surface finish. |

| 2. High Operating Torque or Seizure | – Galling between Sphere and Seat: Under high pressure or with insufficient lubrication, certain metal combinations (like stainless-on-stainless) can adhere to each other. – Media Solidification/Crystallization: Media like syrup or lime slurry can solidify in the valve cavity, “gluing” the sphere in place. – Buildup of Corrosion Products: Oxides and other impurities from a corroding sphere increase friction. | – Optimize Material Pairing: Avoid galling-prone combinations or apply a low-friction coating like ENP to the sphere. – Fikojakojana tsy tapaka & Cleaning: For media prone to solidification, establish a schedule for valve cycling and line flushing. – Use Corrosion-Resistant Materials: Fundamentally prevent the formation of corrosion products. |

| 3. Erosion/Abrasion | – High-Velocity Fluid or Solid Particles: In lines with sand, slurry, or catalysts, fast-moving particles act like sandpaper on the sphere surface, especially during throttling. | – Use Ultra-Hard Materials: Employ ceramic spheres, which are significantly harder than metals. – Apply Surface Hardfacing: Coat metal spheres with Tungsten Carbide (TCC) or a Stellite overlay to create an extremely wear-resistant layer. – Avoid Throttling with Standard Ball Valves: For abrasive services requiring throttling, use specially designed V-port ball valves or other erosion-resistant valve types. |

5. Key Standards Governing Ball Valve Spheres

The professional sphere of manufacturing must adhere to strict international standards that specify requirements for materials, dimensions, and inspection.

API 608 – Metal Ball Valves – Flanged, Threaded, and Welding Ends

- Source: American Petroleum Institute.

- Relevance: A primary standard for ball valves in the petrochemical industry. It specifies requirements for design, materials, wall thickness, testing, and inspection. It provides guiding principles for the sphere’s material selection and wall thickness calculations to ensure safety under pressure.

API 6D – Specification for Pipeline and Piping Valves

- Source: American Petroleum Institute.

- Relevance: Focused on valves for long-distance pipelines, this standard is more stringent. It imposes stricter material requirements for the sphere, including impact testing, and mandates Non-Destructive Examination (NDE) like Radiographic Testing (RT) or Ultrasonic Testing (UT) to ensure the sphere is free of internal defects.

ASME B16.34 – Valves—Flanged, Threaded, and Welding End

- Source: American Society of Mechanical Engineers.

- Relevance: This is a fundamental valve design standard that defines pressure-temperature ratings. The sphere’s design, particularly its wall thickness, must be sufficient to withstand the pressures at its designated rating, and this standard provides the basis for calculation.

ISO 17292 – Metal ball valves for petroleum, petrochemical and allied industries

- Source: International Organization for Standardization.

- Relevance: As the international counterpart to API 608, it similarly details the design, material, performance, testing, and inspection methods for industrial metal ball valves, making it a critical reference worldwide.

Famaranana: A Professional Choice is a Reliable Guarantee

The ball valve sphere is a culmination of technology and craftsmanship. Its quality directly impacts the safety, efficiency, and cost of your fluid control system. As a factory with extensive manufacturing experience, we deeply understand the importance of every detail—from precise material selection and micron-level machining accuracy to strict adherence to international standards.

If you are seeking high-quality valve spheres that meet demanding service conditions and international standards, or if you require expert technical consultation, please do not hesitate to contact us. Let us support your success with our professional knowledge and reliable products.