A paradigm shift is reshaping the European Union’s water industry. Driven by the recastEU Drinking Water Directive (DWD), the market now mandates the use of virtually lead-free materials for all components in potable water systems. For purchasers, engineers, and distributors, sourcing DWD compliant valves is no longer a choice but a critical requirement for market access, legal compliance, and safeguarding public health.

This definitive guide provides a technical framework for navigating these regulations. We will analyze the core requirements of theDWD (EU) 2020/2184, detail the specifications for compliant lead-free brass valves, explain the necessary testing protocols, and present BMAG Factory as an expert lead-free valve manufacturer capable of meeting these exacting standards.

1. Understanding the Regulatory Framework: The EU Drinking Water Directive (DWD)

The sole legislation governing materials in contact with drinking water in the EU is the DWD (EU) 2020/2184. It is imperative to distinguish this from the RoHS directive, which applies to electronics.

Key Regulatory Mandates:

- Parametric Value for Lead Reduced to 5 µg/L: The directive’s most impactful provision is the reduction of the maximum allowable concentration of lead at the consumer’s tap from 10 µg/L to5 µg/L. Full implementation of this limit is required byЯнварь 12, 2036, a deadline established to accommodate the replacement of legacy infrastructure. Sourcing valves for the 5 µg/L lead limit is now a forward-looking necessity.

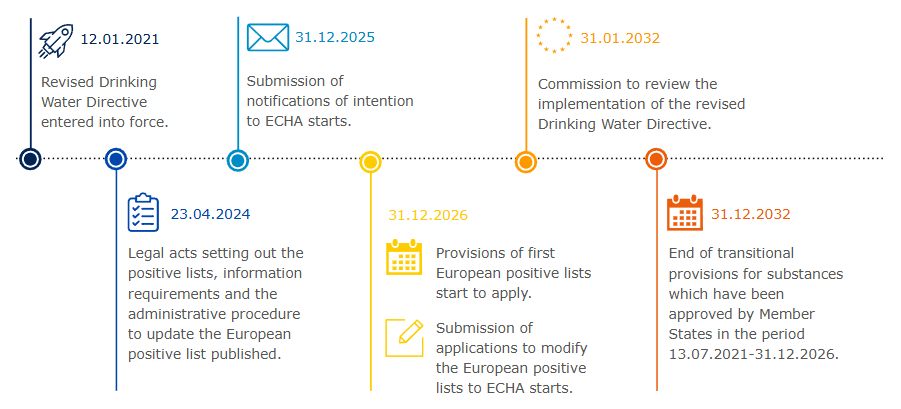

- Harmonized Material Regulations and ECHA Positive Lists: For the first time, the DWD establishes EU-wide minimum hygiene requirements for materials. The European Chemicals Agency (ECHA) is developing“positive lists” of approved starting substances, compositions, and constituents (likeSilicon Brass). Once established (by 2026), any material or substance not on these lists will be prohibited for use in drinking water applications. This replaces disparate national approval schemes and creates a single standard for lead-free valves for the EU market.

Implications for Purchasers: Compliance is no longer simply about a final product passing a test. It is now about proactive material management. A supplier must prove that the fundamental alloys and components used in their valves for EU potable water systems are on the approved ECHA lists and are sourced with full traceability.

2. Material Specification: Compliant Brass Alloys for DWD Compliant Valves

Traditional free-machining brass alloys (E.G., CW617N) contain 2% lead and no longer meet DWD requirements. The industry has shifted to advanced, high-performance lead-free alternatives. As a leadinglead-free brass valve factory, we see one material as the premier choice.

Primary Approved Brass Grade for EU Compliance:

Silicon Brass (CW724R / CuZn21Si3P)

- Composition: This alloy, often marketed under the trade name Ecobrass®, replaces lead with silicon (Si) and phosphorus (P). The exact designation isCuZn21Si3P.

- Performance Advantages:

- Zero Lead Content: It is inherently lead-free, ensuring it can meet the5 µg/L lead limit with a significant margin of safety.

- Superior Corrosion Resistance: Silicon Brass exhibits exceptional resistance to dezincification, a form of corrosion that can degrade traditional brass and lead to component failure.

- High Mechanical Strength: CW724R valves offer mechanical strength comparable to or exceeding that of stainless steel, ensuring durability and long service life.

- Market Acceptance: CW724R is one of the most widely specified and trusted materials on theECHA positive lists and by national regulatory bodies, making it the safest choice for DWD compliant valves.

Жез (CW511L / CuZn38As)

- Composition: Its primary elements are Copper (Cu) and Zinc (Zn), with a key addition of Arsenic (As) to provide excellent Dezincification Resistance (DZR). The official chemical designation isCuZn38As.

- Performance Advantages:

- Ultra-Low-Lead Compliance: It meets the stringent 5 µg/L migration limit of the DWD by maintaining a lead content of ≤ 0.2% at the material level. This controlled, minimal presence of lead ensures full compliance with the most demanding health and safety standards.

- Exceptional Dezincification Resistance (DZR): The addition of Arsenic makes CW511L highly resistant to dezincification, a form of corrosion that can compromise the structural integrity of standard brass in certain aggressive water conditions. This ensures long-term reliability and component lifespan.

- Good Machinability: Compared to inherently harder lead-free alloys, the material properties of CW511L allow for efficient and precise manufacturing processes, ensuring high-quality finished components.

- Market Acceptance: CW511L is officially listed on theGerman Environment Agency (UBA) Positive List of metallic materials hygienically suitable for contact with drinking water. This UBA list is a core component of the 4MS Initiative. But it must simultaneously satisfy two criteria:

- CW511L base composition must conform to the specifications defined in EN 12164 / In 12165.

- Its lead content must meet the stricter hygienic requirement of the German UBA Positive List (≤ 0.1%).

3. Verification of Compliance: Essential Lead Content Testing for Brass Valves

Verifying a supplier’s claims requires documented evidence from two distinct types of testing. A professional lead-free valve manufacturer’s products must pass both tests.

- 1. Compositional Analysis (Verifies the Alloy): This test determines the exact elemental percentage of lead within the brass itself.

- Methodology: The industry standard is Optical Emission Spectrometry (OES), a highly accurate laboratory method. For routine quality control of incoming raw materials and finished goods.

- 2. Migration Testing (Verifies the Product’s Safety in Water): This is the ultimate test for DWD compliance, as it measures the amount of lead that leaches from the finished product into drinking water.

- Methodology: The official European standard is migration testing EN 15664-1. This is a “Dynamic Rig Test” that simulates real-world usage. The valve is installed in a test loop and subjected to repeated cycles of water flow and stagnation over an extended period (weeks or months). Water samples are taken after stagnation periods and analyzed for lead concentration.

4. How to Evaluate and Select a Lead-Free Valve Supplier: A Purchaser’s Checklist

This strategic checklist helps you mitigate risk when sourcinglead-free drinking water brass ball valves and other components.

- ✓ Full Material Traceability: Can the supplier provide Mill Test Reports (MTRs) for every batch of brass raw material? This is non-negotiable proof of composition.

- ✓ Verifiable Test Reports: Do they provide recent, un-redacted test reports from accredited third-party labs for both compositional analysis and, most importantly, migration testing to EN 15664-1?

- ✓ Segregated Production Lines: Does the factory operate physically separate production lines for lead-free and leaded brass? A shared line, even if cleaned, poses an unacceptable risk of cross-contamination.

- ✓ In-Depth Regulatory Expertise: Does their technical team demonstrate a clear understanding of DWD (EU) 2020/2184, the role of the ECHA positive lists, and specific national requirements?

- ✓ Proven Manufacturing Record: Can they demonstrate a long and successful history of manufacturing and exporting CW724R valves specifically for the EU market?

5. Spotlight: BMAG Factory – Your Expert Lead-Free Valve Manufacturer

For purchasers seeking a partner who exceeds compliance requirements, BMAG Factory is an industry leader in the manufacturing of high-performance lead-free brass valves. We have built our operations around the stringent demands of the EU Drinking Water Directive.

Why BMAG is the Premier Choice for DWD Compliant Valves:

- Standardized on Premium CW724R (Ecobrass®): BMAG has standardized its entire lead-free production on CW724R (CuZn21Si3P). This eliminates material ambiguity and guarantees superior mechanical performance, corrosion resistance, and unconditional compliance.

- Rigorous Quality Control and Testing: Every incoming batch of CW724R is verified with an in-house OES spectrometer to confirm its composition. We provide complete documentation, including material certificates and batch-specific migration testing (In 15664-1) reports from accredited laboratories.

- Guaranteed Production Purity: BMAG operates completely segregated production facilities for lead-free products. From raw material storage to melting, casting, and machining, there is zero risk of lead cross-contamination.

- Full Transparency and Traceability: Every lead-free valve shipped from BMAG is fully traceable back to its raw material batch, backed by a comprehensive documentation package to support your compliance audits.

- Expert Regulatory Partnership: Our engineering team possesses deep expertise in theDWD. We act as a technical partner, guiding you through material selection and compliance requirements to ensure your projects are secure and successful in the European market.

By choosing BMAG, you are investing in a certified, traceable, and unconditionally compliant solution that protects public health and secures your business’s future in Europe.