שסתומים הם רכיבי ליבה חיוניים במערכות בקרת נוזלים, and correctly understanding and selecting the right Valve Pressure rating is fundamental to ensuring the safety and stability of the entire system. Incorrect selection can lead to valve leaks, damage, or even severe safety incidents. This guide will serve as an authoritative resource to systematically answer all key questions about valve pressure.

תוֹכֶן הָעִניָנִים

לְמַתֵגWhat is Valve Pressure?

Valve pressure refers to the maximum allowable pressure a valve can withstand at a specific temperature. This concept is typically understood on two levels:

- Nominal Pressure (Pn): This is a reference value used for design, manufacturing, and application, representing the overall pressure-bearing capability of the valve. It is usually identified by “Pn” and is a standardized series. It does not mean the same working pressure can be maintained at all temperatures.

- Working Pressure: This is the actual fluid pressure the valve is subjected to in a real-world application at a specific operating temperature. The working pressure must always be less than or equal to the valve’s maximum allowable pressure at that temperature.

What are Valve Pressure Ratings?

א Valve Pressure Rating is a standardized classification system that categorizes a valve’s pressure-handling capability according to specific standards (like ASME, ב, API).

Concepts and Terminology of Different Valve Pressure Ratings

- Nominal Pressure (Pn): The European standard system (ב 1092-1), based in Bars, is a series of reference numbers related to the valve’s mechanical strength.

- Class Rating (LB): The American standard system (ASME B16.34, B16.5) is a series of classes based on the pressure can withstand at various temperatures. This is key to understanding the valve pressure rating meaning, as it is intrinsically linked to temperature. All types, from a gate valve pressure rating to a ball valve pressure rating, follow this system.

- API Pressure Ratings: The American Petroleum Institute (API) establishes pressure ratings for the oil and gas industry, כְּגוֹן 2000, 3000, 5000, 10000 PSI in API 6A, which are defined working pressure ratings.

What are the Units of Valve Pressure?

- Bar: A common international unit of valve pressure. 1 Bar ≈ 1 atmosphere.

- MPa (Megapascal): The primary pressure unit in the International Valve System of Units (SI). 1 MPa = 1,000,000 Pa.

- Psi (Pounds per Square Inch): An imperial valve unit, very common in North America.

- kgf/cm² (Kilogram-force per square centimeter): A technical atmosphere unit.

How to Identify Pressure Markings on a Valve Body?

The markings cast or stamped on the valve body are the most direct way to identify its pressure capability. Common markings include:

- PN Rating: לְמָשָׁל., PN16, PN25, PN40. This indicates the nominal pressure rating of the valve in Bars and is a core identifier in the European (ב) standard system.

- Class (or Pound Rating): לְמָשָׁל., 150LB, מַחלָקָה 150, 300LB. This is the pressure rating identifier for the American (ASME) standard system. The number does not directly correspond to PSI. A Class 150 valve does not mean it can only handle 150 Psi; its specific capability must be determined from the corresponding pressure-temperature rating chart.

- שְׁקִילָה / CWP: לְמָשָׁל., 600 שְׁקִילָה or 1000 CWP.

- שְׁקִילָה stands for Water, Oil, גַז.

- CWP stands for Cold Working Pressure.

- שְׁקִילָה / CWP are largely interchangeable and indicate the maximum pressure the valve can handle at ambient temperatures (typically -20°F to 100°F or -29°C to 38°C) for water, שֶׁמֶן, and gas media. לדוגמה, א brass ball valve pressure rating שֶׁל “800 שְׁקִילָה” means it can safely handle 800 PSI under cold, non-shock conditions.

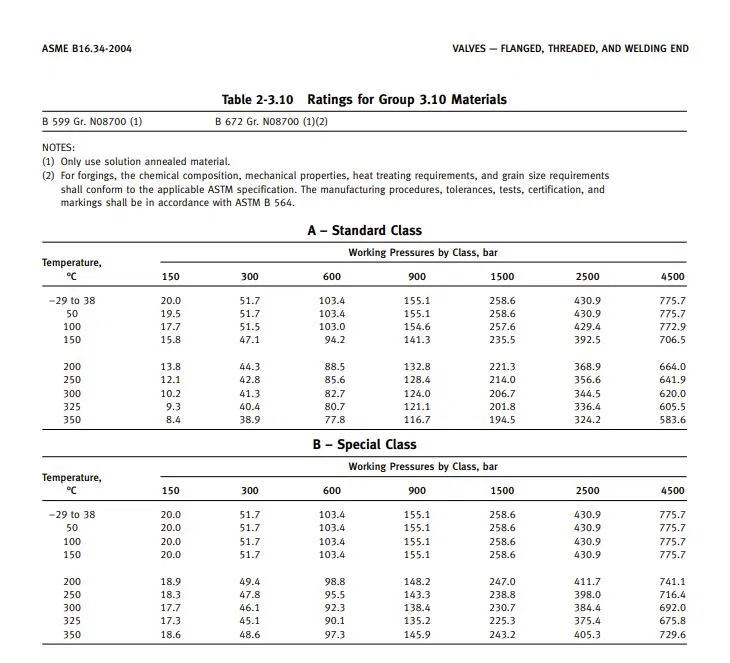

Working Pressures by Class– ASME B16.34-2004

How to Calculate Between Different Pressure Units?

Mastering unit conversion is essential for accurate calculations. Here are common valve pressure conversions:

- 1 MPa ≈ 145 Psi

- 1 Bar ≈ 14.5 Psi

- 1 Bar = 0.1 MPa

- 1 kgf/cm² ≈ 0.98 Bar ≈ 14.2 Psi

How to Convert Between Different Valve Pressure Ratings?

This is a critical and often misunderstood concept: There is no direct mathematical formula to convert between PN ratings and Class ratings!

This is because they are based on different standard systems, reference temperatures, and material groups. למרות זאת, for convenience in engineering applications, the following approximate correspondence chart can be referenced. This chart is for reference only; precise selection must be based on the specific standard.

לוּחַ 1: Valve Pressure Class vs. PN Rating Conversion Reference

| Class Rating | Pn (Nominal Pressure) |

|---|---|

| Class 150 | Pn 20 |

| Class 300 | Pn 50 |

| Class 400 | Pn 68 |

| Class 600 | Pn 110 |

| Class 900 | Pn 150 |

| Class 1500 | Pn 260 |

| Class 2500 | Pn 420 |

The Relationship of Valve Pressure-Temperature (P-T) Ratings

ה Valve Pressure-Temperature Rating is the most important concept in valve selection. It dictates that the maximum allowable working pressure of a valve decreases as the operating temperature increases.

For all valves following ASME standards, the pressure rating is defined by a valve pressure temperature rating chart. This chart, based on the valve’s material (לְמָשָׁל., carbon steel A216 WCB, stainless steel A351 CF8M) וכן Class rating, details the maximum allowable working pressure at various temperatures.

לְמָשָׁל, a Class 150 carbon steel valve might handle close to 285 PSI at ambient temperature, but as the temperature rises to 300°C (572°F), its maximum allowable pressure could drop below 100 Psi.

What are the Key Factors Affecting Valve Pressure Ratings?

- Valve Body Material: This is the decisive factor. Different materials (carbon steel, stainless steel, alloy steel, brass) have vastly different mechanical strengths and creep resistance at various temperatures.

- Operating Temperature: As mentioned, temperature directly impacts material strength and thus dictates the valve’s pressure-handling capability.

- Design Standard: Different valve pressure rating standard documents (לְמָשָׁל., ASME, API, DIN) have different requirements for design, materials, and testing.

- Connection Type: The strength and sealing performance of different connection types like flanged, welded, or threaded ends affect the overall pressure rating of the valve.

- Valve Type: The internal design of different valves, such as a check valve pressure rating versus a gate valve, means their potential weak points for pressure and sealing can differ.

Valve material, operating temperature and pressure comparison table

| Valve Material | Pressure (Pn) | טֶמפֶּרָטוּרָה | Media |

|---|---|---|---|

| Gray Cast Iron | ≤ 1.0 MPa | -10°C to 200°C | מַיִם, steam, אֲוִיר, גַז, and oil products. |

| Malleable Cast Iron | ≤ 2.5 MPa | -30°C to 300°C | מַיִם, steam, אֲוִיר, and oil products. |

| Ductile Iron | ≤ 4.0 MPa | -30°C to 350°C | מַיִם, steam, אֲוִיר, and oil products. |

| Acid-Resistant High-Silicon Ductile Iron | ≤ 0.25 MPa | < 120מעלות צלזיוס | Corrosive media. |

| פלדת פחמן | ≤ 32.0 MPa | -30°C to 425°C | מַיִם, steam, אֲוִיר, hydrogen, ammonia, nitrogen, and petroleum products. |

| Copper Alloy | ≤ 2.5 MPa | -40°C to 250°C | מַיִם, seawater, oxygen, אֲוִיר, oil products, and steam. |

| High-Temperature Copper (Alloy) | ≤ 17.0 MPa | ≤ 570°C | Steam and petroleum products. <br> פֶּתֶק: Selection must comply with valve pressure-temperature standards. |

| Cryogenic Steel (Low-Temperature Steel) | ≤ 6.4 MPa | ≥ -196°C | Ethylene, propylene, liquefied natural gas (LNG), liquid nitrogen, etc. |

| נירוסטה (Acid-Resistant) | ≤ 6.4 MPa | ≤ 200°C | Nitric acid, acetic acid, etc. |

How to Select the Right Valve Pressure Rating

Follow these steps for a scientific and safe selection process:

- Determine Operating Conditions: Clearly define the system’s maximum working pressure and maximum operating temperature. This is the foundation for selection.

- Select Valve Material: Choose the appropriate body and trim materials based on the fluid’s corrosiveness, טֶמפֶּרָטוּרָה, and other factors.

- Consult the P-T Rating Chart: Find the valve pressure rating chart corresponding to your chosen material.

- Verify and Apply a Safety Margin: On the chart, locate your maximum operating temperature and find the corresponding maximum allowable pressure. Ensure this pressure value is greater than your system’s maximum working pressure, and include a safety margin (typically 10%-25% is recommended).

- Finalize the Rating: Select a Valve Pressure rating whose P-T curve completely covers your operating point.

Example: A system has a maximum working pressure of 45 Bar (approx. 653 Psi) and a maximum temperature of 300°C (572°F). The medium is steam, and the material is ASTM A216 WCB carbon steel. By consulting the ASME B16.34 standard, you would find that a Class 300 valve is rated for approximately 50 Bar at that temperature, whereas a Class 150 valve’s rating is far lower. לָכֵן, you must select a Class 300 or higher pressure rating.

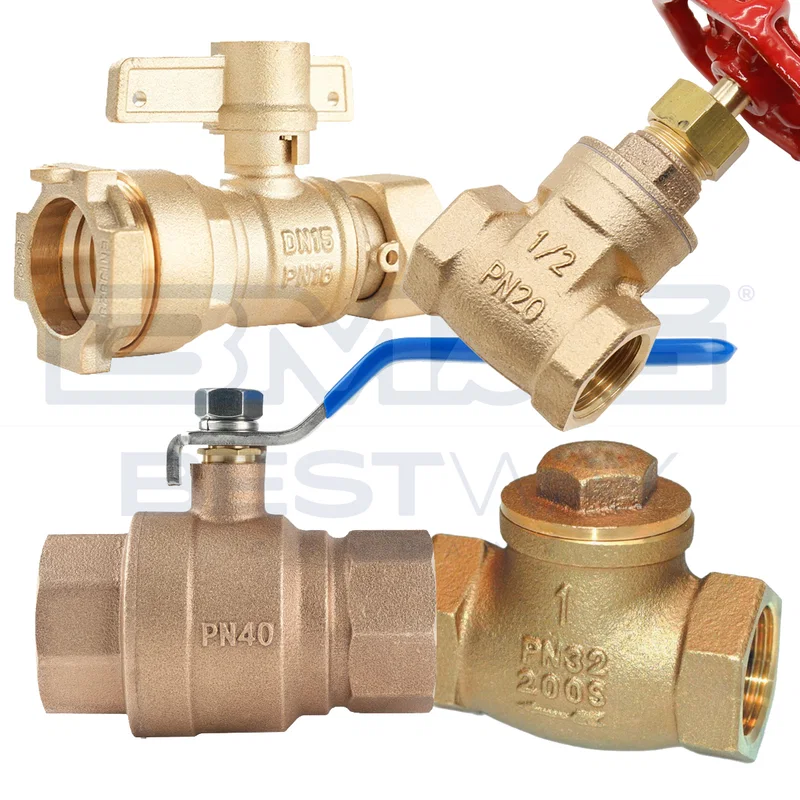

Find Your Ideal Valve Solution – Optimize with BMAG