Talaan sa sulud

MagtagadWhat Is a Bronze Valve?

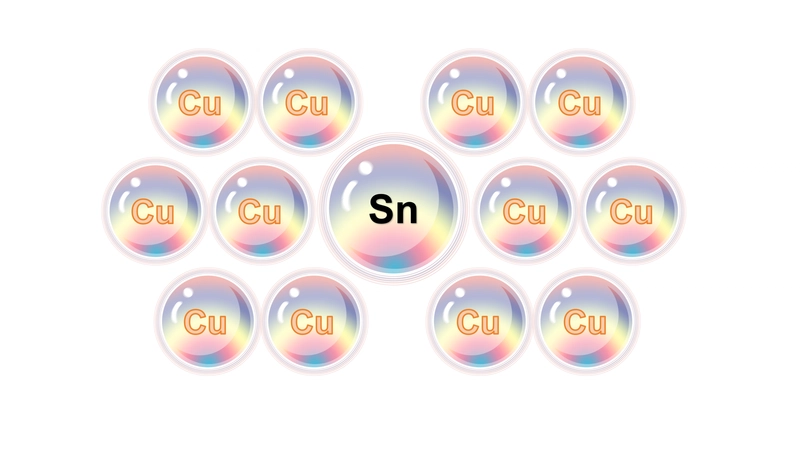

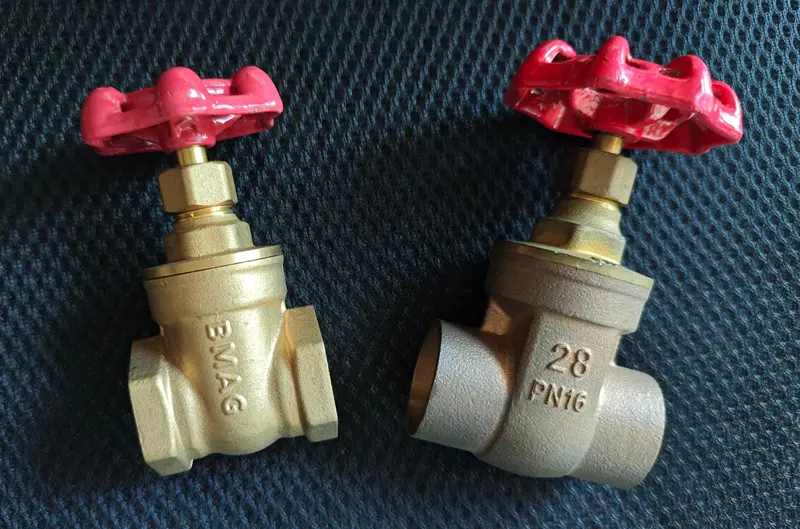

Ang mga balbula nga tumbaga mga balbula nga hinimo sa tumbaga nga metal. They utilize the characteristics of bronze material to meet the special requirements for valves in different environments and industries. The main elements in bronze are copper and tin.

In bronze valve, the copper content is usually between 80-90%, and the tin (Sn) content is typically between 10-20%. The higher tin content makes bronze valves with greater hardness and strength, and better resistance to saltwater corrosion. It is widely used in the fields of ocean, industry, and shipping.

What Is a Balbula nga tumbaga?

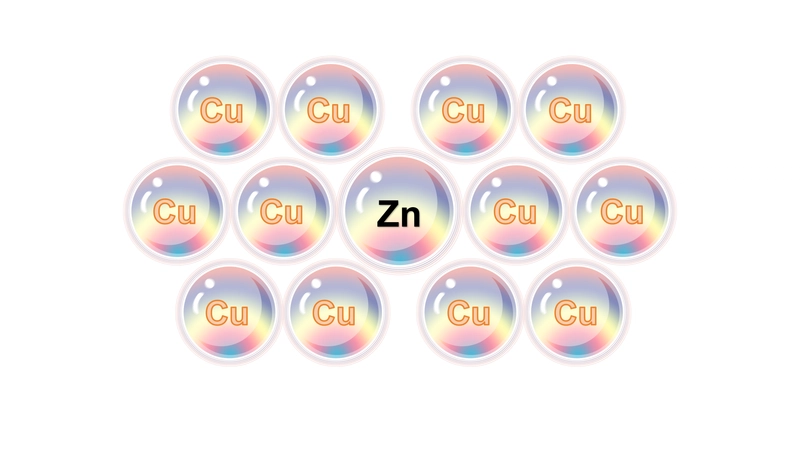

In brass valve the copper content is usually between 50-60%, and the zinc (Zn) content is typically between 30-40%. It’s good for its durability and good thermal conductivity. Brass valves are used in plumbing, HVAC, oil and gas, and automotive.

Nga labi ka maayo? BRONZE VALVE vs Brass Balita?

In terms of valve durability, bronze valves are better than brass valves.

Due to the different atomic arrangement structures caused by chemical composition, which fundamentally alter their mechanical properties.

Why Do Bronze Valves Exhibit Superior Performance?

It is easier to understand the principle of the enhanced properties of bronze compared to pure copper from its atomic and microstructural characteristics:

1. Solid Solution Strengthening (Effect of Tin Atoms):

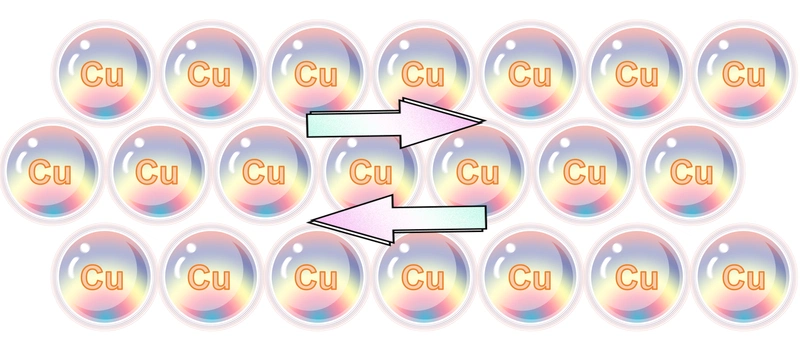

In pure copper, atoms are arranged in a relatively orderly lattice. When an external force is applied, these atomic layers can slide past each other along planes where the interatomic forces are weaker. This is why pure copper is relatively soft, has low strength, but exhibits good ductility.

When larger tin atoms substitute some of the copper atoms in the lattice, they cause a distortion. This distortion disrupts the regular arrangement, creating a structure that is more resistant to this atomic slippage, almost like an “interlocking” effect. Consequently, a greater external force is needed to make these layers slide.

2. Strengthening Chemical Compound (Second Phase Strengthening):

When the tin content in bronze exceeds approximately 10%, or after specific heat treatments, intermetallic compounds (such as Cu₃Sn, Cu₆Sn₅, etc.) can form. These compounds are distinct phases within the bronze. They are typically hard and brittle. When these hard particles are distributed throughout the softer bronze matrix, they act as obstacles to the movement of dislocations (the mechanism of plastic deformation), further increasing the overall hardness and strength of the bronze.

Why is a Bronze Valve Harder than a Brass Valve?

Let’s analyze from an atomic structure perspective.

In brass, which has a higher zinc content, zinc atoms substitute for some of the copper atoms. This substitution also creates an “interlocking” effect or lattice distortion, making brass harder than pure copper.

Hinoon, tin atoms are significantly larger than zinc atoms.

- Zinc (Zn) has an atomic mass of approximately 65 and an atomic diameter of about 268 picometers (pm).

- Tin (Sn) has an atomic mass of approximately 118 and an atomic diameter of about 316 picometers (pm).

Because tin atoms are larger, when they substitute copper atoms in the bronze alloy, they cause a greater degree of lattice distortion. This more substantial distortion creates a more pronounced “interlocking” effect, offering greater resistance to the movement of atomic layers under stress.

Busa, due to the larger size of tin atoms causing more significant lattice strain, bronze exhibits higher strength and hardness compared to brass.

Mga Balbula nga Bronse Corrosion: Causes, Prevention & Solutions

Do bronze valves have better corrosion resistance?

Oo, bronze valves generally exhibit good corrosion resistance.

To understand why, let’s first consider pure copper.

In air, pure copper forms a protective layer of cuprous oxide (Cu₂O) or basic copper carbonate (patina), which slows down corrosion. Hinoon, in saltwater and seawater (water containing chloride ions), these chloride ions are highly aggressive. They can break down this protective film, leading to pitting corrosion or uniform corrosion of the copper. The cuprous oxide (Cu₂O) layer often appears black and might look like a stain, but it doesn’t affect the material’s performance; if aesthetics aren’t a concern, it doesn’t require treatment.

Bronse, on the other hand, is able to form a more stable passivation film. The presence of tin (Sn) is crucial here, as it helps to form a denser, more stable, and better-adhering passivation layer on the bronze surface. This film is typically a composite of tin oxide (SnO₂) and cuprous oxide (Cu₂O). Tin oxide itself possesses good chemical stability, particularly in neutral or weakly acidic media containing chlorides. Pa pa, if aluminum (Al) is present in the bronze alloy (as in aluminum bronze), it contributes by forming a protective aluminum oxide (Al₂O₃) layer, which also provides excellent protection against seawater corrosion.

Why are bronze valves more resistant to saltwater corrosion than brass valves?

Brass valves exhibit poor resistance to saltwater corrosion. This is primarily because brass contains a significant amount of zinc, and zinc is a relatively active element. In saltwater environments, which are rich in chloride ions (Cl–), brass is prone to a corrosion process calleddezincification. During dezincification, the more active zinc Selective leaches out of the alloy, leaving behind a porous, copper-rich structure. This process leads to a reduction in the strength of the brass, and its color change from yellow to red. Dezincification is a critical and highly detrimental form of corrosion for brass valves; the resulting degradation in performance directly impacts the valve’s quality and operational safety. Busa, brass valves should absolutely be avoided in saltwater applications.

In contrast, bronze valves have very good resistance to saltwater corrosion. The tin (Sn) present in bronze is a much less reactive element compared to zinc and does not readily corrode in saltwater. Pa pa, the tin oxide (SnO₂) film that forms on the bronze surface acts as a protective barrier. This stable oxide layer effectively hinders chloride ions in seawater from reacting with the underlying copper, thus preventing further corrosion.