- What is DZR Brass?

- What is Dezincification?

- DZR Brass Grades and Compositions

- Current Standards and Regulations

- Marking Requirements for DZR Fittings

- Testing Methods for DZR Brass

- Advantages of DZR Brass Valves

- BMAG DZR Brass Valves

Mesing otporan na dezinciranje (DZR Brass) je postao važan materijal u vodovodnoj industriji, posebno za primjenu ventila. The number of users choosing DZR Brass Valves is increasing, indicating that the public’s requirements for water quality and valve materials are increasing steadily.

Sadržaj

PrebaciWhat is DZR Brass?

DZR brass(Otporan na dezinfikaciju) is a specialized copper alloy engineered to resist dezincification, a corrosion process that plagues standard brass in certain environments.

What is Dezincification?

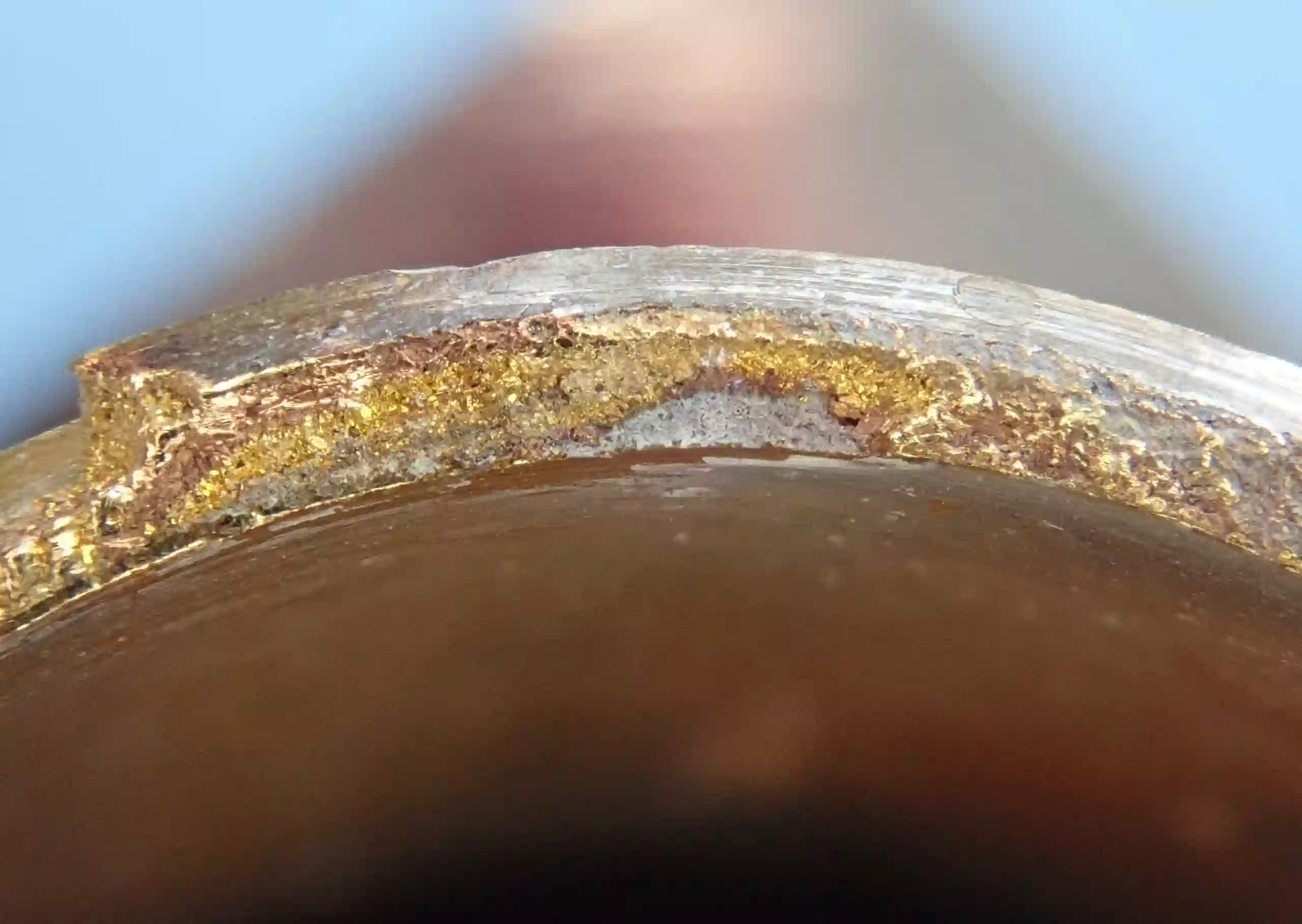

Dezincification, or the leaching of zinc, occurs when zinc is selectively removed from the brass alloy, leaving behind a porous.

The occurrence of dezincification corrosion in brass is closely linked to the zinc content in copper-zinc alloys. Typically, when the zinc content is below 15%, dezincification corrosion is unlikely to happen; however, the alloy’s erosion resistance is compromised. Increasing the zinc content can enhance both the strength and erosion resistance of the alloy, but it also raises the risk of dezincification corrosion.

When the zinc content exceeds 20%, the zinc tends to dissolve preferentially in aqueous solutions. This process leaves the copper structure porous, leading to a decrease in the strength of the brass.

Dezincification of brass is more likely to happen in seawater and solutions containing salts, such as NaCl and CuCl2.

The resistance mechanism in DZR brass is achieved through control of the alloy composition. Incorporating small amounts of elements such as As/Sb/P/B/Al and rare earth, and maintaining specific copper-to-zinc ratios, create an alloy that effectively inhibits zinc leaching in water conditions.

DZR Brass Grades and Compositions

Common Brass Grades

CW602N/CZ132 (CuZn36Pb2As):

CW724R (CuZn21Si3P):

CW511L (CuZn38As):

Current Standards and Regulations

Various countries and regions have established standards for DZR brass and its use in valves:

European Union: U 12165 (Copper and copper alloys – Wrought and unwrought forging stock)

United Kingdom: Bs jedan 12165, BS 6920 (Suitability of non-metallic products for use in contact with water intended for human consumption)

Australia/New Zealand: AS/NZS 4020 (Testing of products for use in contact with drinking water)

United States: ASTM B124 (Standard Specification for Copper and Copper Alloy Forging Rod, Bar, and Shapes), NSF / ANSI 61 (Drinking Water System Components – Health Effects)

Međunarodni: ISO 6509 (Corrosion of metals and alloys – Determination of dezincification resistance of copper alloys with zinc)

Marking Requirements for DZR Fittings

Different countries have specific requirements for marking DZR brass fittings:

Plumbing fittings that are resistant to dezincification are appropriately marked, with the letters “CR” (Corrosion Resistant) or DZR (dezincification resistant) in the UK, and the letters “DR” (dezincification resistant) in Australia.

Testing Methods for DZR Brass

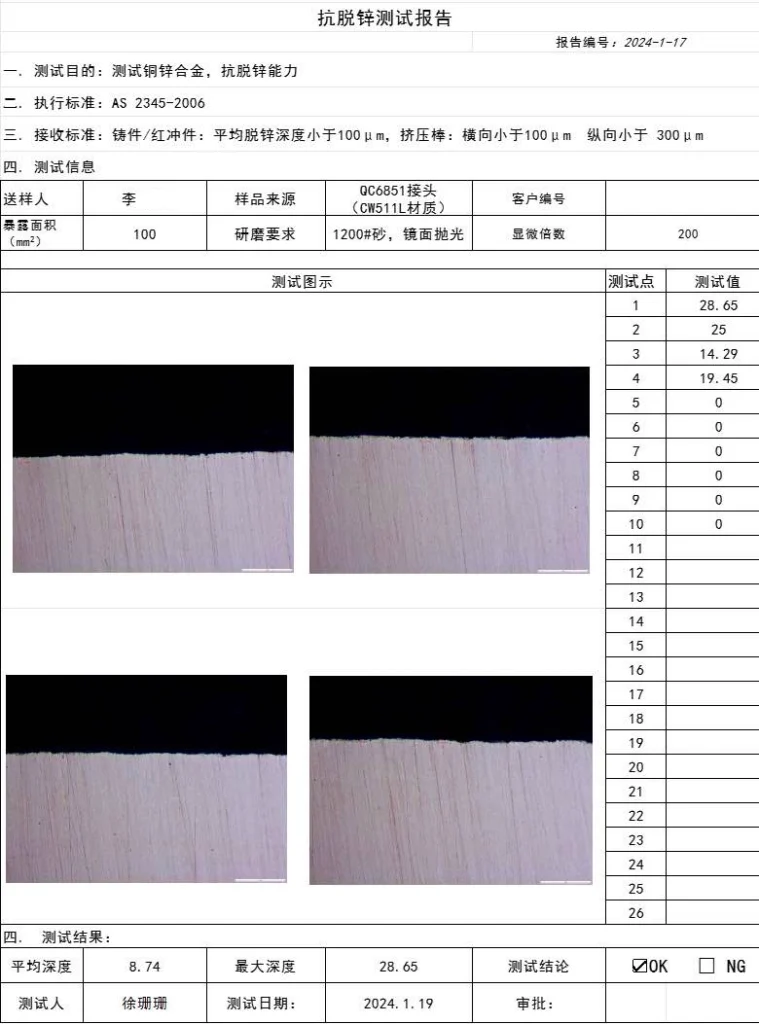

The primary test method for DZR brass is outlined in ISO 6509:

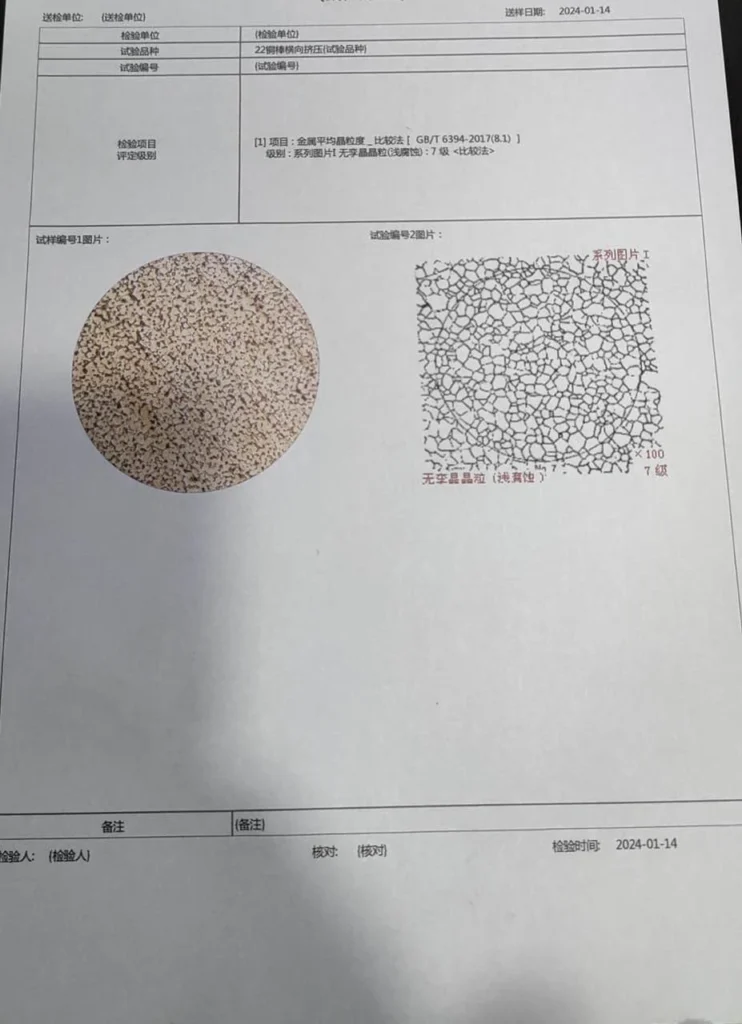

① Sample preparation: Specimens are polished and cleaned.

② Exposure: Samples are immersed in a copper chloride solution at elevated temperatures (usually 75°C) for a specified period (typically 24 sati).

③ Measurement: After exposure, samples are sectioned and the depth of dezincification is measured using microscopy techniques.

④ Evaluation: The dezincification depth is compared to specified limits, typically less than 200 micrometers for a 24-hour test.

Advantages of DZR Brass Valves

Enhanced corrosion resistance, particularly against dezincification

Longer service life compared to standard brass valves

Maintenance of structural integrity in aggressive water conditions

Compliance with stringent drinking water regulations

BMAG DZR Brass Valves

DZR brass valves represent a significant advancement in plumbing technology, offering superior corrosion resistance and longevity in water systems. BMAG DZR brass valves i armature enhance the strength of systems exposed to highly corrosive water, reducing the need for frequent maintenance and part replacements.